Mission Impossible in orbit

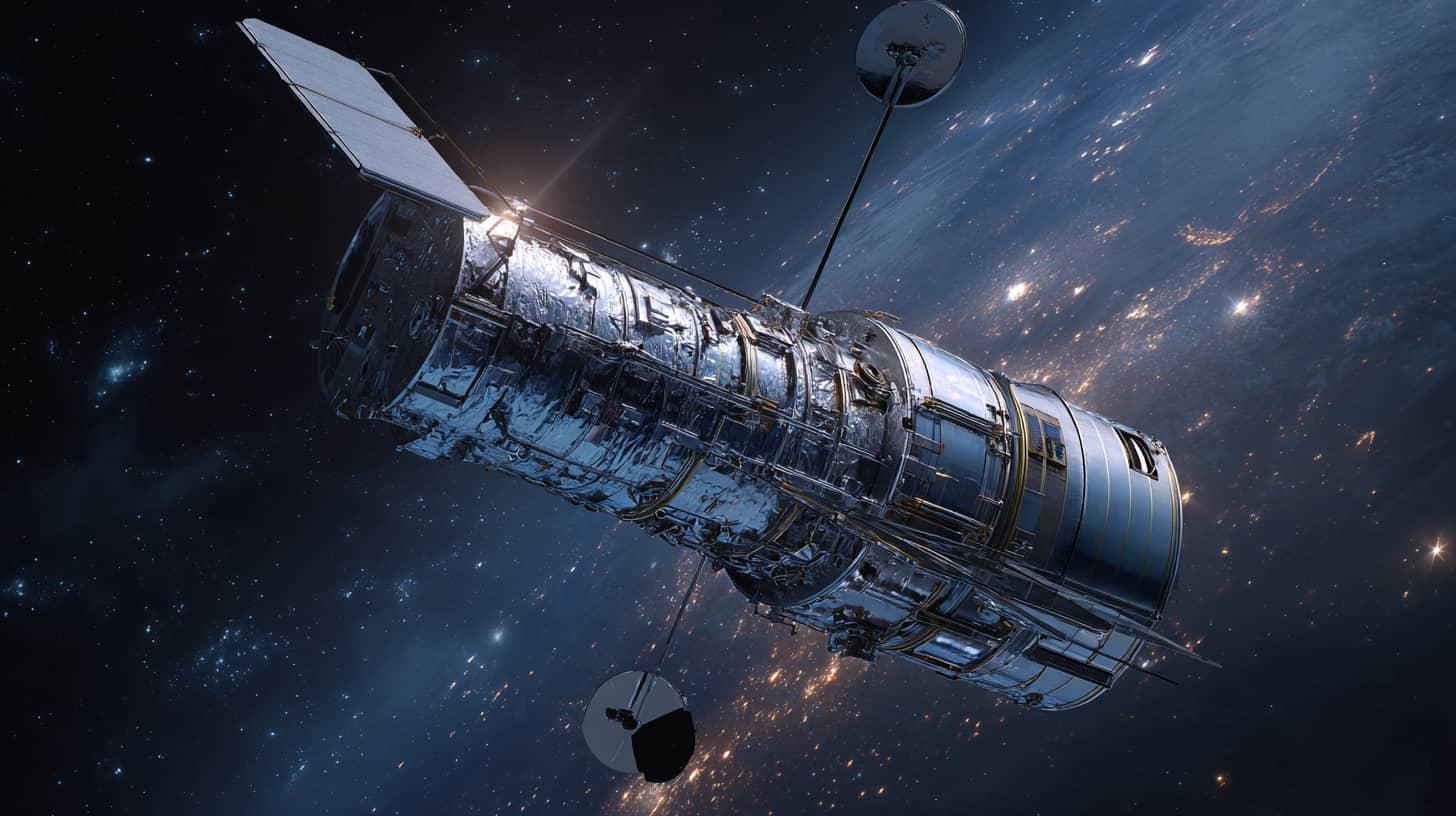

Imagine: 550 kilometers above the earth hovers a telescope that has been delivering perfect images for over 30 years. The Hubble Space Telescope proves how revolutionary surface technology works even in the vacuum of space. This is where coatings make the difference between scientific breakthroughs and billions in investment.

Space is the ultimate stress test for any surface. Temperature fluctuations from minus 100 to plus 120 degrees Celsius, aggressive UV radiation without atmospheric protection and micrometeorite bombardment continuously attack all materials.

Why normal coatings fail in space

Vacuum changes everything. Without air molecules, normal paints evaporate within hours. Outgassing contaminates sensitive optics. Adhesives lose their bonding power. Standard surface protection specialist systems are completely useless here.

Space coating service requires completely different materials. Space-qualified systems undergo years of testing in vacuum chambers. Each material must remain stable at extreme temperatures and must not release any volatile substances.

Satellite surface treatment uses special silicone and fluoropolymer systems. These resist atomic oxygen, which attacks organic materials in low orbits. Metallic coatings provide additional protection against cosmic radiation.

Innovation through extreme conditions

What makes Hubble's coatings so special? The answer lies in the perfect adaptation to space conditions. Optical component coatings for mirrors and lenses achieve nanometer precision. Even the smallest impurities would make astronomical observations impossible.

Thermal control coatings regulate the temperature precisely. White surfaces reflect sunlight, black surfaces absorb heat. Multi-layer insulation protects sensitive instruments from temperature fluctuations.

Particularly innovative: conductive coatings dissipate static electricity. Dangerous charges can build up in a vacuum, which would destroy electronic systems.

Maintenance in zero gravity

How do you repair coatings in space? Hubble's maintenance missions with space shuttles were masterpieces of precision. Astronauts replaced entire instrument modules in special protective suits.

Every surface repair had to work under space conditions. Special tools prevented contamination through gloves. Coating analysis laboratory on Earth simulated all the work steps before the missions.

Surface testing service providers developed non-destructive test procedures for the orbit. Spectroscopic analyses by the telescope optics themselves monitored the condition of the coatings.

Quality control for eternity

Space qualification requires extreme standards. UV resistance testing is carried out with unfiltered solar radiation. Vacuum chamber coating tests simulate decades of space conditions.

Coating Inspection Service uses electron microscopy to monitor molecular changes. Every outgassing is measured, every thermal expansion is calculated. Surface protection quality control achieves scientific precision.

Salt spray test expert procedures are replaced by aggressive chemical tests. Atomic Oxygen simulations reproduce the corrosive effect of the upper atmosphere.

Technology transfer to earth

What works in space revolutionizes terrestrial applications. Aerospace coating specialist findings flow into aviation coating service projects. Extreme high-altitude flights benefit from space-proven systems.

Precision surface technology adapts Hubble's purity standards. Semiconductor Equipment Coating uses vacuum-compatible materials. Laser Technology Coating applies optical precision coatings.

Particularly valuable: temperature-resistant formulations. Power plant surface protection in high-temperature zones benefits from space-age materials. Gas turbine coating expert teams rely on proven extreme environment solutions.

Maintenance strategies without return

Modern satellites must function without maintenance. Coating system planning calculates 15-year service life without human intervention. Self-monitoring systems report surface changes to earth.

Drone special coating benefits from autonomous monitoring concepts. Messtechnik Oberflächenschutz adapts remote sensors for industrial applications. Predictive maintenance using AI algorithms detects problems before failures occur.

Coating consulting B2B today includes space qualifications. Coating expert teams think in decades instead of years. FROSIO certified coating standards are extended to aerospace requirements.

The future of space surface technology

New generations of space telescopes place even higher demands. James Webb and future observatories will operate in even more extreme environments. Cryogenic equipment coating for minus 230 degrees Celsius is becoming a standard requirement.

Self-repairing coatings could make maintenance missions superfluous. Nano-robots repair microscopic damage automatically. Smart coatings adapt their properties to changing space conditions.

Hubble has been proving this for three decades: The right surface technology makes the impossible possible. What reveals the secrets of the universe today will revolutionize terrestrial technologies tomorrow. Every Hubble image is proof of the power of perfect coatings.